Heating Systems

Improving efficiency and reducing emissions of residential direct heating equipment

Improving efficiency and reducing emissions of residential direct heating equipment

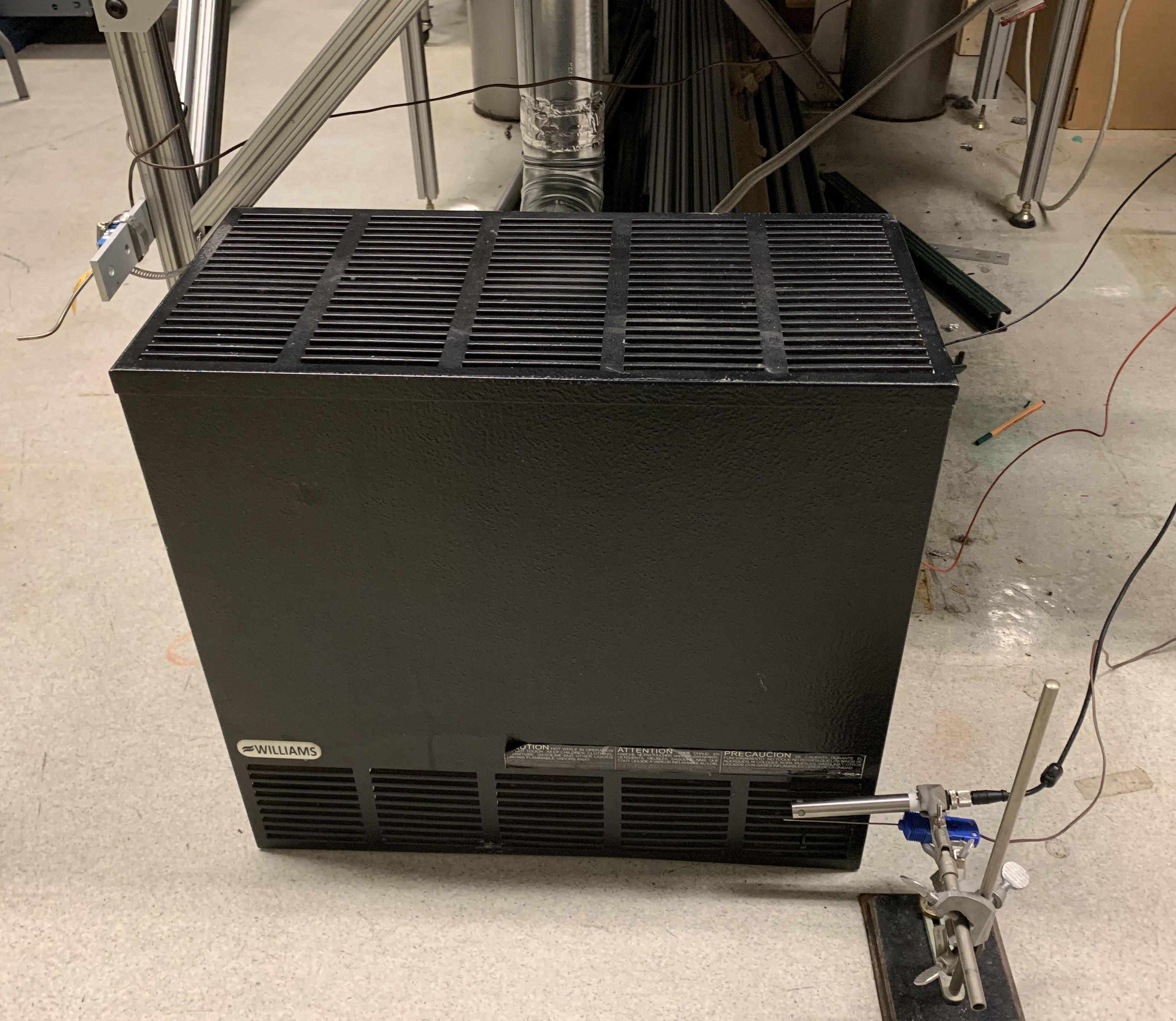

Funded by the California Energy Commission, we will develop cost-effective strategies to reduce natural gas use and emissions from direct heating equipment (e.g. wall furnaces) in California. This project will also evaluate thermal comfort and indoor air quality benefits for the households heated by this equipment. Laboratory experiments will validate and compare efficiency and emissions from currently operating units and emerging technologies. The data will expand current knowledge about actual direct heating equipment performance and the safety and health risks this equipment may pose to households where they are installed. The data will also inform the development of potential technological and installation improvements that will increase this equipment’s performance and reduce its risks.

Related publication: LBNL Report: Laboratory Evaluation of Direct Heating Equipment

Ultra low-emission burner for residential appliances

Ultra low-emission burner for residential appliances

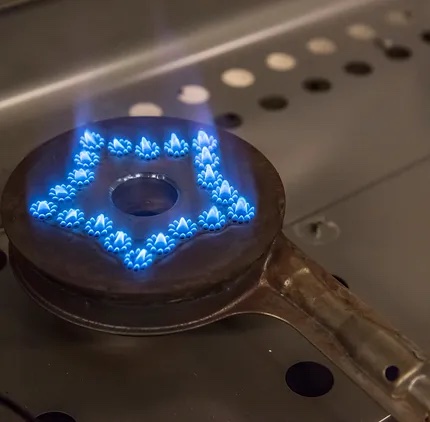

Building from the California Energy Commission funded project developing a residential cooktop burner (see past projects), we have partnered with industry to evaluate the performance of the burner in a commercial appliance. If successful, this burner will be integrated into a their new line of technology.

Demonstration of industrial systems with real-time response to fuel stock variability

Demonstration of industrial systems with real-time response to fuel stock variability

Funded by the California Energy Commission, this project aims to demonstrate, in a commercial boiler installed at a water treatment plant, a low-emissions combustion system capable of switching from biogas, a renewable fuel, to a conventional gaseous fuel (natural gas or propane) in real-time without disrupting the boiler’s operation. Fuel-switching combustion systems will incentivize small to medium facilities, e.g. hospitals, hotels, and large supermarkets, to use their waste streams to fulfill their energy needs. This technology benefits California by promoting a larger renewable energy portfolio and improving air and water quality. The development involved advancements in burner, fuel sensing, and control technologies. Based on laboratory tests that showed the capability of these technologies to perform real-time fuel switching with ultra-low emissions, a fully-functional pre-commercial burner system and control was design and installed to the boiler. Regrettably, the demonstration could not proceed due to time and administrative constraints coupled with host-site availability. The results and knowledge from the developments have clearly shown the technical feasibility of deploying real-time fuel-switching system in industrial settings.

Low NOX, high turndown burner for on-demand water heater

Low NOX, high turndown burner for on-demand water heater

Current state-of- the art on-demand (tankless) water heaters are expensive due to multi-stage burner banks that require complex controls. This project, funded by the New York State Energy Research and Development Authority, developed an efficient, cost-effective, ultra-low emissions natural gas on-demand (tankless) water heater for commercial and residential buildings. The new design will have higher efficiency and lower manufacturing costs than current tankless water heaters. The enabling technology is the low swirl burner (LSB), developed at Lawrence Berkeley National Laboratory (LBNL). The LSB is simple, robust, and fuel-flexible; it offers high-performance (30:1 turndown) with ultra low emissions while requiring less control hardware. Integrating the LSB to tankless water heaters will circumvent the complicated burner staging practices used in current state-of- the-art tankless water heaters.

Related publication: LBNL Report LBNL-1007236

Low emissions, residential cooktop burner

Low emissions, residential cooktop burner

This project, funded by the California Energy Commission, adapted the Lawrence Berkeley National Laboratory (LBNL) Ring-Stabilizer Burner combustion technology for residential and commercial natural gas fired cooking appliances (such as ovens, ranges, and cooktops). LBNL originally developed the Ring-Stabilizer Burner for a NASA funded microgravity experiment. This natural draft combustion technology reduces NOx emissions significantly below current SCAQMD emissions standards without post combustion treatment. Additionally, the Ring-Stabilizer Burner technology does not require the assistance of a blower to achieve an ultra-low emission lean premix flame. The research team evaluated the Ring-Stabilizer Burner and fabricated the most promising designs based on their emissions and turndown.

Related publication: LBNL Report LBNL-1006345

Effects of gas composition on water heater emissions

Effects of gas composition on water heater emissions

As a part of a larger effort to evaluate the potential air quality impacts of using liquefied natural gas in California, this project investigated the effects of effect of varying natural gas blends and associated Wobbe number (a measure of the energy delivery rate for appliances that use orifice- or pressure-based fuel metering) on pollutant emissions from residential water heaters in controlled laboratory experiments. Experiments were conducted on eight storage water heaters, including five with “ultra low-NOX” burners, and four on-demand (tankless) water heaters, all of which featured ultra low-NOX burners. Pollutant emissions were measured for carbon monoxide (CO), nitrogen oxides (NOX), nitrogen oxide (NO), formaldehyde and acetaldehyde as the water heaters were operated through defined operating cycles using fuels with varying Wobbe number. This project was funded by the California Energy Commission.

Related publication: LBNL Report LBNL-6626E